Undergraduate Thesis

Modification of the Experimental Setup for Measuring Viscoelastic Response of Super Elastic Shape Memory Alloy (SMA) Rod under Bending and Twisting

Modification of the Experimental Setup for Measuring Viscoelastic Response of Super Elastic Shape Memory Alloy (SMA) Rod under Bending and Twisting

Objective

- Examine the stress relaxation of SMA rod under torsional loading at different angles.

- Examine the stress relaxation of SMA rod subject to bending at constant strain.

- Contrast the findings with traditional materials.

Method

- Performed experimental testing using a custom-built apparatus with wood and metal.

- Used semi-automatic data logging system.

- Performed a series of tests, collected data, and used that data to plot graphs for analysis.

Setup

- Developed an L-shaped wooden platform with a ratchet-protractor system for torsional stress relaxation tests.

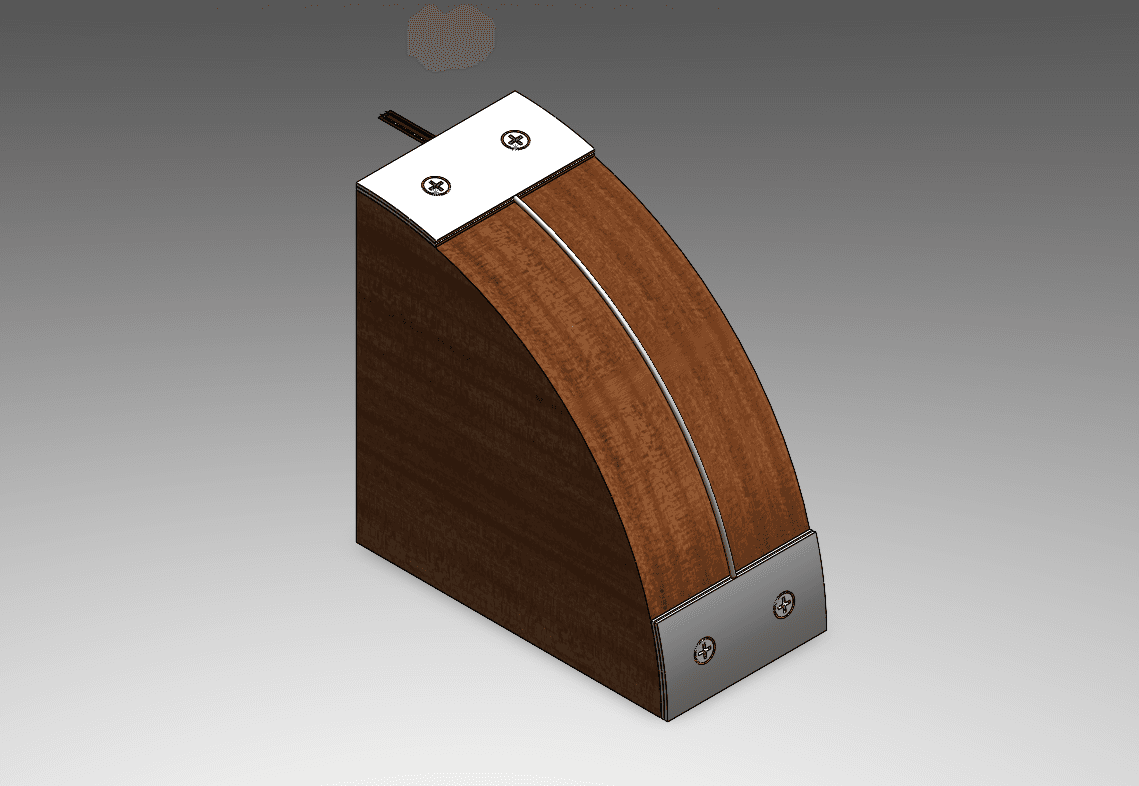

- Used a wooden quarter circle for bending stress relaxation test.

- Utilized an Arduino Mega and Force Sensing Resistor (FSR) for real-time load measurement

- Used a specimen of Nicket-Titanium (NiTi) SMA Rod with a diameter of 2mm.

Fig. 1: Experimental Setup for Torsional Stress Relaxation

Setup

- Developed an L-shaped wooden platform with a ratchet-protractor system for torsional stress relaxation tests.

- Used a wooden quarter circle for bending stress relaxation test.

- Utilized an Arduino Mega and Force Sensing Resistor (FSR) for real-time load measurement

- Used a specimen of Nicket-Titanium (NiTi) SMA Rod with a diameter of 2mm.

Fig. 1: Torsional Stress Relaxation at different angles

Results

- Exhibited exponential stress relaxation for bending and torsion in accordance with Maxwell's Viscoelastic Model

- Torsional stress relaxation showed consistency across different angles from zero to 90 degree

- In torsional loading, an increase in the twisting angle correlates with a higher percentage of stress release.

- Compared to Stainless Steel and Copper, SMA's phase transition characteristics allow for faster and greater stress reduction, especially at higher twisting angles.